Plastic injection molding part

- High efficiency- fast production.

- Complex part design.

- Enhanced strength.

- Flexibility- material and color.

- Reduced waste.

- Low labor costs.

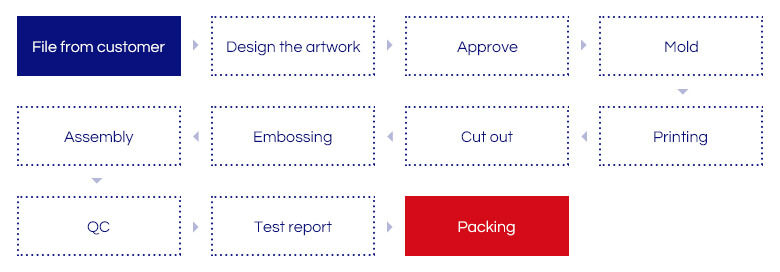

One-stop plastic injection molding service of Foundation is meaning that we can offer you the plastic components molding service start from the plastic components 3D design, molds manufacturing, plastic components injection molding or plastic components surface finishing treatment and plastic components assembling.

One-stop plastic components injection molding service can be started from the plastic components 3D design, it can also be started from mold making or the customers supplying the ready molds. After the plastic injection molding service, Foundation also can offer the plastic components surface treatment service with assembling and packaging services.

Injection moulding is used to create many things such as wire spools, packaging, bottle caps, automotive parts and components, toys, pocket combs, some musical instruments (and parts of them), one-piece chairs and small tables, storage containers, mechanical parts (including gears), and most other plastic products available today.

Payment: T/T

Delivery: Within 15-30days after confirming the order

Advantage: